Printed Intelligence in Finland – From Roll to Business

Printed intelligence in Finland focuses on cost and energy efficient roll-to-roll manufacturing, advanced scalable materials and creation of new business.

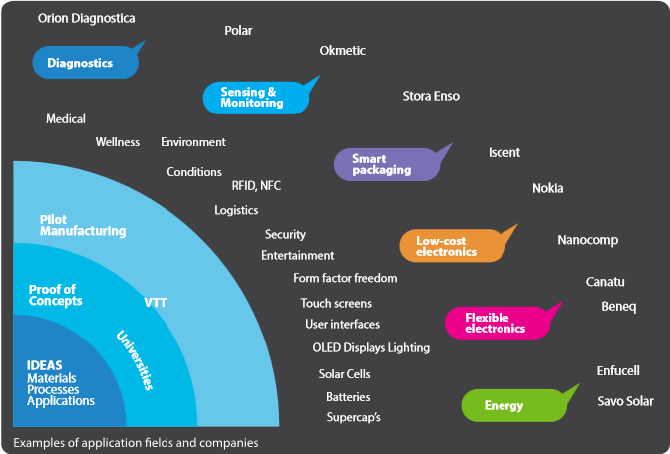

The key is to combine materials and processing know-how with applications such as smart packaging, diagnostics, organic electronics, organic light emitting diodes (OLEDs), lighting and solar cells. These provide important enablers for the critical needs of flexible and organic electronics – already today.

ref. Tekes Functional Materials Programme, Final Report

Several SMEs have already transferred their recent research to industrial applications. For example:

Beneq has developed the first industrial roll-to-roll atomic layer deposition (ALD) equipment, efficiently providing the critical barrier coatings for flexible electronics and photovoltaics.

Canatu manufactures uniquely flexible, highly transparent, conductive carbon nanomaterial-based thin films for customised touch sensors and formable 3D (three-dimensional) touch modules. This provides superior alternative to indium tin oxide (ITO), which is brittle and based on scarce natural resources.

Iscent produces printable holographic-like light-scattering films for smart packaging and security applications by hot embossing technology – without any inks or metals.

Nanocomp produces micro- and nanophotonics solutions by thin foil reel-to-reel technology.

Okmetic uses printing technologies in manufacturing of MEMS devices.

Focused research is conducted at several universities, such as Tampere University of Technology, Åbo Akademi University, University of Oulu, as well as VTT Technical Research Centre of Finland, which today has excellent pilot-scale manufacturing facilities.

Example project: Processes for MEMS by Inkjet Enhanced Technologies (Prominent).

These are just examples of the key players of the Finnish Printed Intelligence ecosystem which is today active in R&D, piloting and implementation – and building business with top-notch international partners.

VTT Printed Intelligence – World class

by Riku Rikkola

VTT is a leading provider of R&D services in printed intelligence and its applications. With staff of more than 100 experts in the field and unique pilot facilities, VTT can carry out concept development, prototyping and upscaling to manufacture printed, flexible and plastic electronics products.

VTT Printed Intelligence has spent the past ten years focusing strongly on research into highly efficient roll-to-roll manufacturing processes. This has been supported by PrintoCent investments in new facilities and research work in jointly funded projects and demonstrators. In recent years, more and more emphasis has been put on systems, integration and product development. Key to this has been the introduction of VTT’s roll-to-roll component assembly line, and active collaborations with partners in the PrintoCent, the industrialization cluster for printed intelligence technologies and products. Combining all these strengths, VTT Printed Intelligence has moved further into application-driven research.

VTT Printed Intelligence offers world-class competence in understanding materials and processes. Special attention is given to tailoring materials for compatibility with printing and other roll-to-roll manufacturing processes. Experience has shown that process development for specific applications is also critical. At VTT Printed Intelligence this is carried out in parallel with materials and ink development. As the printed roll is very seldom the final product, system integration plays a key role in product development.

System integration enables the roll-to-roll production of flexible electronics products by introducing silicon-based or flexible components onto printed foils. Especially, competitive benefits can be gained in applications requiring large-area production with a limited added-component count. This silicon-hybrid approach enables the integration of low power processing and communication capabilities into flexible systems and products. Small and thin components can be fully integrated without compromising flexibility.

VTT Printed Intelligence works across these technologies with a strong focus on manufacture upscaling. This means that instead of restricting work to small-scale, novel devices in solar cells for example, our attention is on large-area cells and systems. Similarly in transistors, the goal is to create printable backplanes and integrated printed circuits whilst ensuring the repeatability of the manufacturing processes. VTT Printed Intelligence is frequently engaged as the upscaling partner of choice for lab-scale, proven technology. Our strength is in assisting customers not only with proof of principle but also with proof of production.

Read more:

www.vttprintedintelligence.fi

www.printocent.net