FIMECC’S Industry-led Doctoral School Digitalizes Material Science

FIMECC’s Breakthrough Materials Doctoral School presented its latest results at the Manufacturing Performance Days (MPD) event in Tampere on June 10. This intensive research collaboration which already involves 37 doctoral works sets special focus on multiscale modelling and so called integrated computational materials engineering (ICME). New digital tools are used to build comprehensive understanding and to control material properties from microstructure to product design. This will speed up the product development and greatly improve the predictability of product endurance in demanding industrial applications.

FIMECC BSA (Breakthrough Steels and Applications) and HYBRIDS (Hybrid Materials) programmes, both managed jointly by Spinverse, consist of several industry-led projects involving more than 60 companies. They are tied together by a Fundamentals and modelling research entity that concentrates on understanding critical basic phenomena and computer-based modelling and simulation of material properties. It ensures that the programmes have a strong scientific basis and also enables an operating model where the projects can utilize the latest scientific knowledge, methods and modelling tools. A substantial amount of the research work is done within the 37 doctoral thesis works of the FIMECC Breakthrough Materials Doctoral School. shared by the two programmes.

“The doctoral school participants tackle jointly defined scientifically challenging and critical research questions together with industrial partners and leading international research groups. The researchers, their supervisors and international partners form a unique multidisciplinary research community”, emphasizes Professor David Porter from University of Oulu, who gave a scientific keynote lecture that set up the seminar day.

“FIMECC’s Doctoral School educates the right kind of multidisciplinary experts, which is one of the most important factors enabling the competitiveness of the Finnish industry”, says Marke Kallio (Metso Minerals), who gave an industrial keynote speech at the seminar.

Doctoral School published latest research results at the MPD2015 event

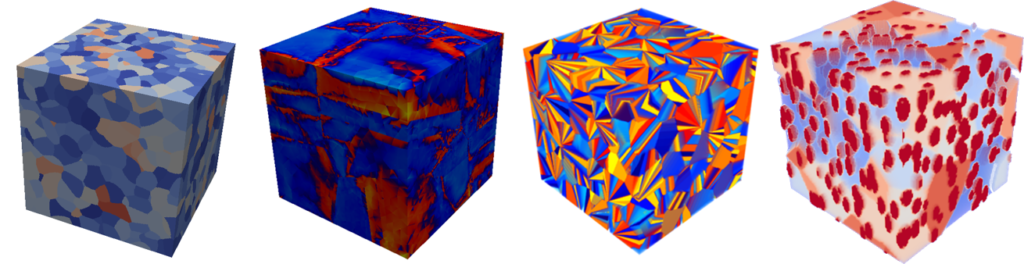

Tatu Pinomaa (VTT & Aalto University) studies the wear properties of thermally sprayed composite coatings. To support the experimental work he has developed multiscale modelling which enables the prediction of the functional properties of these special coatings in their real application environments via microstructural analysis. International collaboration plays an important role in his work. Tatu has recently returned from his research exchange to Montreal (McGill University) whose competence in microstructural modelling he has successfully combined with macroscale structure models.

Tatu Pinomaa (VTT & Aalto University) studies the wear properties of thermally sprayed composite coatings. To support the experimental work he has developed multiscale modelling which enables the prediction of the functional properties of these special coatings in their real application environments via microstructural analysis. International collaboration plays an important role in his work. Tatu has recently returned from his research exchange to Montreal (McGill University) whose competence in microstructural modelling he has successfully combined with macroscale structure models.

Matti Lindroos from Tampere University of Technology (TUT) has examined wear phenomena of high-strength steels. Specific tests carried out with test equipment developed in the TUT Wear Center have simulated the real wear conditions in e.g. mining industry and rock crushing. The tests combined with precise microstructural models pave the way of understanding and controlling material behaviour. Matti has done modelling work during his six-month exchange period in France (Centre des Matériaux, Mines ParisTech).

Mohammad Dabiri from Lappeenranta University of Technology has developed the simulation of fatigue and failure analysis of ultra-high strength steels, while Anna-Maija Arola from Oulu University has created a simulation model for the formability of the same steels. The combination of modelling and specific experimental work produces important new knowledge that is needed in e.g. renewing the design rules of different machinery in order to fully utilize the good properties of new high strength steels, for example via lighter structures and decreased fuel consumption.

Elisa Isotahdon from TUT studies the prevention of corrosion losses in neodymium-based (Nd-Fe-B) magnets. These strong magnets make wind power generators more energy efficient and mechanically reliable, but in the offshore application environment corrosion is a challenge. Elisa has demonstrated that holistic understanding of corrosion mechanisms in relation to the material, structure as well as the magnetic field and including them in the modelling is the key in assessing the actual long-time properties and performance.

New value networks, business and competitiveness

The multidisciplinary projects of FIMECC BSA and HYBRIDS programmes solve critical research questions via application-driven material development creating solutions to the future needs of several industry sectors. The work involves a large group of SMEs and numerous companies applying these materials in various industries (e.g. metals, engineering, cleantech, energy, process, bioeconomy, transportation…). The programmes build new industrial value chains which can actively and systematically implement the research results and pave the way for new international business opportunities.

“The intensive collaboration between companies and the young talents of the doctoral school creates valuable materials know-how of the digital era. This kind of intellectual equity and concrete solutions created can boost Finland into a new rise”, says Dr. Markku Heino, FIMECC BSA and HYBRIDS programme manager from Spinverse.

Read more:

FIMECC HYBRIDS: http://www.fimecc.com/programs/hybrid

FIMECC BSA: http://www.fimecc.com/programs/bsa

More information:

Dr. Markku Heino, Spinverse Innovation Management Oy

Programme Manager, FIMECC BSA & HYBRIDS

Prof. Kenneth Holmberg, VTT

Director, FIMECC Breakthrough Materials Doctoral School